Case Study: Distribution Network Optimization in EMEA

Client: Chemical Company

10.12.2024

Background

A global leader in coating systems, sought to optimize its distribution network across North America and EMEA. Facing high logistics costs and complexity due to multiple distribution centers, Client's network included 41 active sites in EMEA and 29 in North America, serving distinct business units in Industrial, Mobility, and Refinish. The company aimed to reduce these costs while maintaining or improving service levels.

Objectives

1) Streamline the distribution network to reduce operational expenses

2) Maintain service levels for different business units, with lead times of 1–3 days for the respective BUs

3) Enhance sustainability through reduced CO₂ emissions and improved handling processes

4) Minimize redundancies and eliminate costly or underutilized sites

Challenges

The client faced strict regional regulations, high warehousing costs, and the need to balance logistics between 3PL and owned sites. Specific challenges included:

- High transportation costs from interfacility inefficiencies.

- Need for region-specific solutions to account for regulatory and logistical nuances.

Approach & Methodology

Miebach Consulting conducted a comprehensive analysis,

which included:

1. Data Validation and Baseline Assessment

Site visits, data visualization with Power BI, and mapping current network flows for accurate cost and service analysis.

2. Scenario Development: Three primary scenarios were proposed

Scenario 1: Reduction of sites with clusters, using one main hub per region.

Scenario 2: Enhanced lead times with 1- to 3-day delivery options.

Scenario 3: A single hub for all European distribution (excluding the UK and Turkey).

3. Optimization Models

The team applied advanced modeling for each scenario to assess factors such as transportation costs, warehousing costs, working capital, and service levels. These models also included sensitivities to handle fluctuations in growth and logistics costs.

Implemented Solution

Implementing regional hubs and reducing the number of locations for a cost-efficient distribution network

|

Based on scenario analyses, a cluster-based approach with regionally optimized hubs was recommended. The final solution included:

Warehouse Reduction: Targeted reduction from 41 to a minimum of 30 sites in EMEA.

Site-Specific Adjustments: Specific site strategies, such as consolidating Italian warehouses, shifting some functions within the UK and Ireland to a single large facility, and assessing logistics options in EMEA.

Transportation and Inventory Management: Improvements in fill rates and outbound processes, along with frequency adjustments for cost efficiency. |

|

Result & Benefits

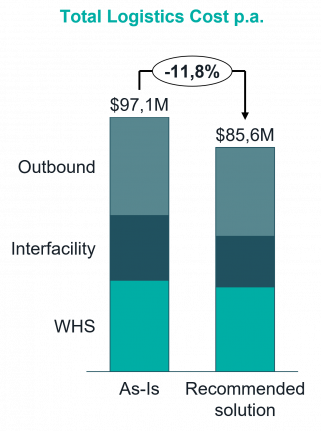

Network optimization indicated 12% annual savings with possible additional 4% from reduced delivery frequency

1. Cost Savings: An estimated $16.1 million in annual savings ($11.5M through Network optimization)

- Optimization of Outbound Flows and customers to warehouse allocation ($3.7M).

- Interfacility efficiency improvement through better truck utilization & less double handling ($5.5M).

- Elimination of expensive and redundant sites, reducing fixed costs by approximately ($2.1M).

- Additionally, reducing outbound delivery frequency can save up to $4.5M.

2. Service Enhancements

- Improved OTIF (On-Time In-Full) performance and overall service levels.

- Reduced average lead times by 12% for key customers.

3. Environmental and Financial Gains

- CO₂ emissions reduced through optimized transportation and fewer interfacility moves.

- 8.6 million USD reduction in working capital by minimizing inventory holding requirements.

- Enhanced negotiating position for commercial terms due to consolidation of warehousing operations.

+ Long-Term Viability

Miebach’s optimized network offers the client a robust foundation for future growth, allowing flexibility to adapt to changing business conditions and regional demands without compromising service levels.

Contact