Sourcing, Procurement and Manufacturing

Introduction

Concious, Strategic, Ready for whatever is to come

Why your supply chain’s upstream matters more than ever.

Today’s supply chains look very different from those even five years ago. Offshoring is giving way to nearshoring. Supplier risks are magnified by geopolitical tensions and compliance requirements. Cost efficiency is key after years of inflation. And buyers demand transparency at every step.

At Miebach, we believe that a resilient supply chain starts long before the warehouse. Sourcing, procurement, and manufacturing form the strategic foundation of supply chain success, shaping everything from cost structure to customer experience. When approached with precision and purpose, these capabilities do more than manage spend. They create resilience, unlock growth, and help your business adapt to whatever comes next.

Relevance of Sourcing, Procurement & Manufacturing’

The importance of addressing the first links in your supply chain

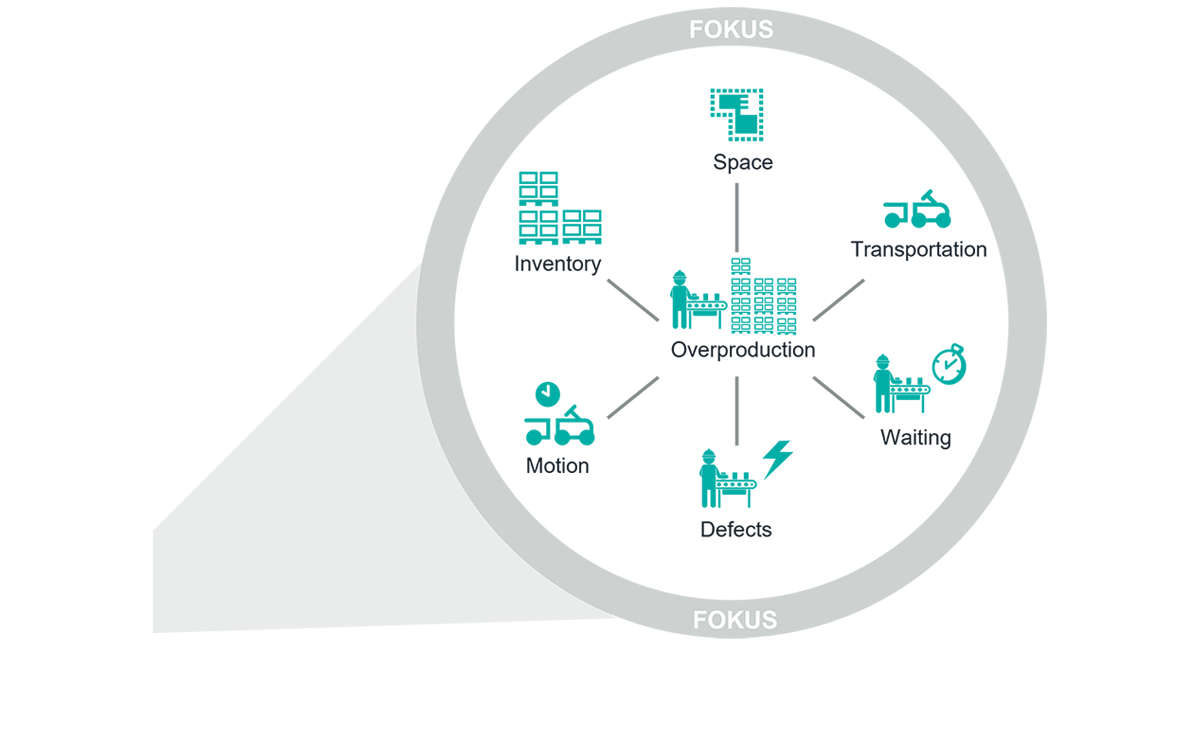

Without a doubt, companies must consider conscious sourcing, strategic procurement management, and future-proof manufacturing to ensure that they:

Mitigate risks

By strategically addressing where, how, and with whom to produce, companies reduce their exposure to geopolitical disruptions, regulatory non-compliance, or supplier issues.

Gain a competitive advantage

A solid sourcing and manufacturing base allows you to reduce cost, accelerate time to market, ensure product availability, and better respond to customer demands for customization.

Generate sustainable value

It's not just about controlling costs, but about aligning the supply chain with ESG objectives, strengthening brand reputation, and meeting legal, customer, and investor expectations.

Timing

When is the right time to do this?

The answer is: now. Especially in organizations experiencing:

- High inflation rates and the need for cost efficiency.

- Excessive dependence on single or distant suppliers, which increases vulnerability.

- Regulatory and reputational pressure on sustainability and traceability.

- Growing customer demand for customized products and fast delivery.

In addition, they should be activated as a priority in strategic transformation scenarios: mergers, acquisitions, international expansion, product line diversification, or industrial footprint redesign.

How can Miebach help?

Our unique approach

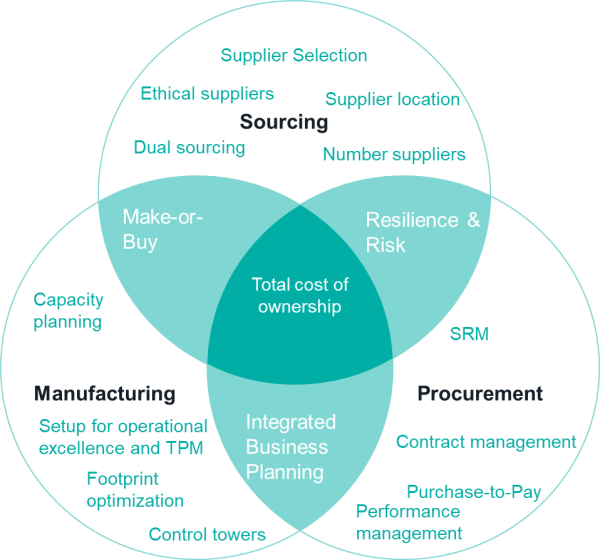

Miebach tackles complexities with a comprehensive, data-driven approach:

- We have extensive experience in projects of all types and for all types of companies.

- We take a comprehensive, end-to-end view, from sourcing strategy to operational execution.

- Our team has global knowledge of the supply chain, which it applies by incorporating local and regional nuances in each case.

- We use proprietary risk analysis methodologies and optimization tools that allow us to anticipate issues.

- We integrate sustainability from the outset rather than adding it later, ensuring that sourcing and manufacturing models meet ESG objectives from the start.

- We generate tangible and rapid results, with projects that deliver both short-term improvements (cost, availability, speed) and long-term structural advantages.

We also collaborate with our clients to jointly provide clear and reliable answers to critical questions such as:

- Where should we establish production? Make-or-buy decisions, footprint strategy, capacity planning.

- Who should we work with? Supplier selection, risk and resilience assessments.

- How can we reduce costs and increase impact? Total cost of ownership, cost reduction, ESG alignment.

Tangible benefits

Whether rethinking a single-supplier strategy or designing a production network closer to your customers, we guide decisions that deliver end-to-end results. For a supply chain ready to meet any challenge and help you stay ahead of your competitors.

What can we help you with?