Miebach Study 2025: Supply Chain Transformation Is the New Normal

Executive Summary

25.09.2025

|

New Miebach Study Reveals Priorities, Success Factors and Pitfalls

In today’s volatile and fast-evolving business environment, supply chain transformation (SCT) is a strategic enabler not only to stay competitive, but also to continuously improve and grow.

To better understand how organizations in the DACH region are navigating this challenge, Miebach conducted a comprehensive study.

The results offer a clear and data-driven view into the types of transformations being pursued, what drives them, and what determines their success or failure.

|

Transformation is the new normal

|

The study confirms that transformation is not a one-off event but a continuous process. Surveyed organizations reported conducting an average of 5.7 supply chain transformation initiatives in the last five years. Over 80% of the surveyed organizations reported having conducted at least two SCTs in the past five years, with 25% reporting five or more.

The most common transformation types include:

|

Transformation is ongoing: over 80% of organizations have repeatedly restructured, upgraded IT and digitalized logistics. |

The results show that transformations are multi-faceted, combining organizational, technological, and process changes.

Network configuration changes (opening, closing, or consolidating facilities) were undertaken by roughly half of respondents.

Sales & Operations Planning (S&OP) has been a focus for 4 in 10 companies, indicating that many are striving to improve cross-functional integration between sales forecasts, production, and inventory planning.

Only about one-third of companies have started leveraging AI or advanced analytics in their supply chain (38%). Similarly, only one-third have significantly improved digital connectivity with external partners (e.g. via supplier portals or control tower dashboards).

What makes transformation successful?

|

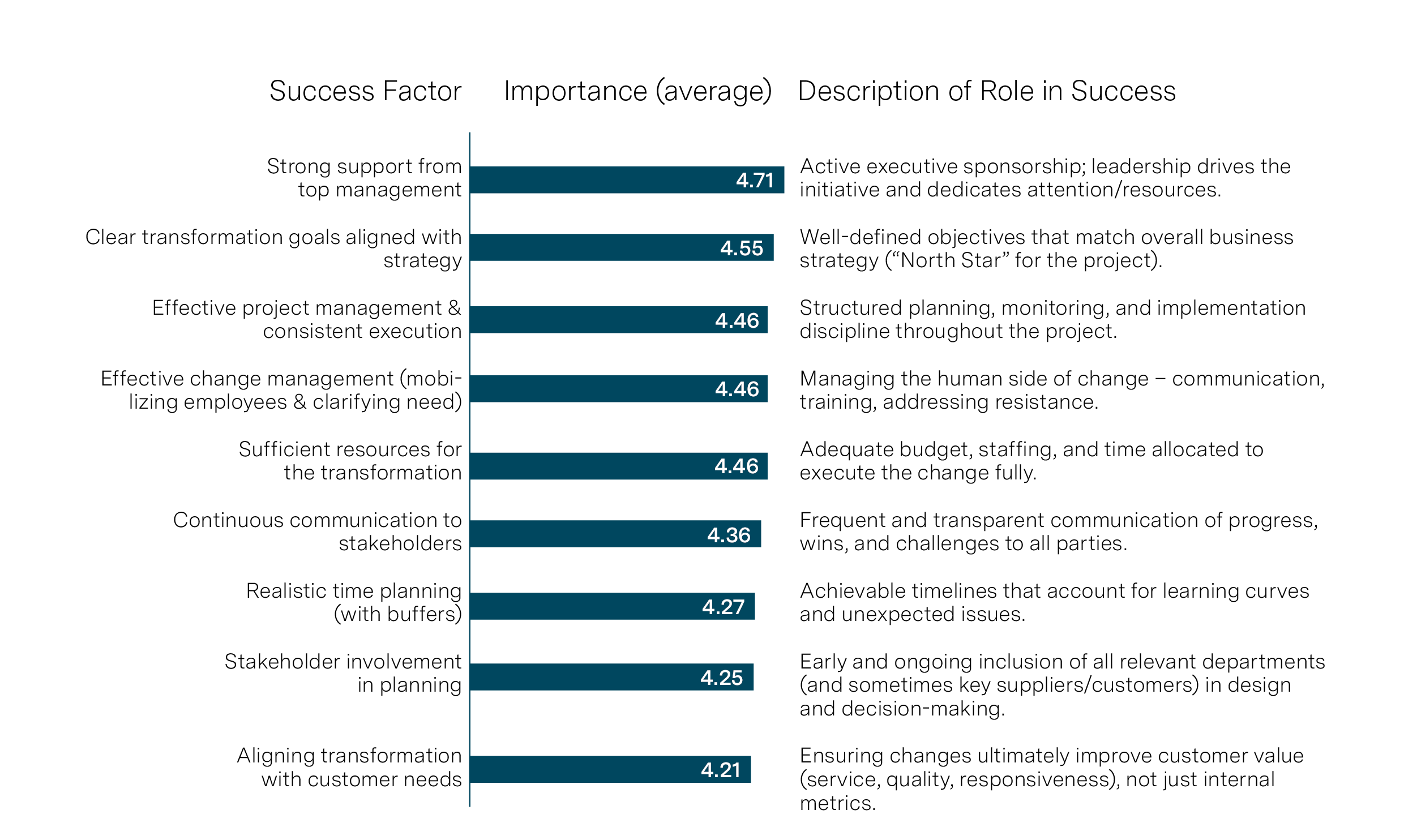

The study identifies a clear formula for success:

These findings make it clear that transformation succeeds when leaders drive it with clarity and purpose. Structured project and change management provide the backbone for reliable execution. Open communication and realistic timelines build trust and foster lasting acceptance. Actively involving stakeholders and a focus on the end-customer and cross-functional involvement ensures the transformation yields |

Supply Chain Transformation wins with leader- ship, strategic goals and communication. |

What gets in the way?

|

The most impactful barriers to transformation success partly mirror the absence of key success factors like lack of top management support (4.41) and unclear misaligned goals (4.29) but also involve other factors like:

Interestingly, while external or technical solutions are helpful, they are not seen as decisive. The human and organizational dimensions matter most.

Without strong leadership, transformation goals often remain vague or misaligned with broader corporate strategy. Implementation suffers when risks are underestimated and project management lacks structure.

Poor communication and insufficient stakeholder involvement create resistance and hinder progress. Unclear messaging and unrealistic timelines further fuel internal pushback and undermine change efforts. |

Overcoming challenges relies on communication, stakeholder engagement, strong project management, and clear, persistent goals. |

Success Factors and Barriers in Transformation

Executive leadership is the top success factor – without active C-level support, even strong transformation initiatives struggle!

Key Recommendations and Takeaways for Supply Chain Managers

|

Ensure visible and continuous support from top management. Get leadership to clearly articulate why the transformation is needed and how it aligns with business strategy. |

|

Establish specific, quantifiable targets that tie to strategic objectives. Use these KPIs to measure progress and reward success. Regularly review progress against milestones and adjust plans as needed. |

|

Treat transformations as formal projects with dedicated teams and budgets. Don’t understaff. Assign your best people and augment with external expertise if needed. Use robust project management practices. Deploy a structured change management plan. |

|

Treat transformations as formal projects with dedicated teams and budgets. Don’t understaff. Assign your best people and augment with external expertise if needed. Use robust project management practices. Deploy a structured change management plan. |

|

Use consultants or technology partners to accelerate progress and import expertise. Consider establishing an internal “Center of Excellence” for supply chain transformation to retain knowledge and manage continuous improvement. |

|

Focus on technologies that directly address your pain points or enable your goals. Avoid shiny-object syndrome; every tech investment should have a business case. Before implementation, streamline the underlying process, then digitize. Involve end users to ensure employees adopt new tools effectively. |

|

Keep the end customer in mind when transforming. Transformations aligned to delivering more value to customers tend to gain stronger support internally and externally. |

|

The job isn’t over at go-live. Monitor the new process or system post-implementation to ensure it’s producing the desired results and to make adjustments. Build a culture of continuous improvement: the organizations in the study averaging 5+ projects didn’t view transformation as one-and-done, but as a continuous process. |

|

Here’s a quick summary of the study: Link |

The full results report of the Miebach Supply Chain Transformation Study 2025 with detailed insights and practical recommendations can be requested via the form above.

Contact