Case Study: Global S&OP Design & Roll-out

How Miebach enhanced the tactical planning and alignment of a Global Pharmaceutical Manufacturer

13.11.2025

Client & Project Background

- Leading Pharmaceutical Manufacturer with global production and distribution footprint.

- Diverse portfolio and multi-layered organization across multiple business units.

- Complex supply structure with competition for capacity across products, markets and business units.

Business Challenges

Our client had been carrying out an increasingly fragmented and non-standardized tactical planning process across its business units and product categories. Their organizational complexity and poor process alignment resulted in a lack of decision speed and transparency. The S&OP production volume focus did not properly consider strategic and financial targets.

Objectives and Deliverables

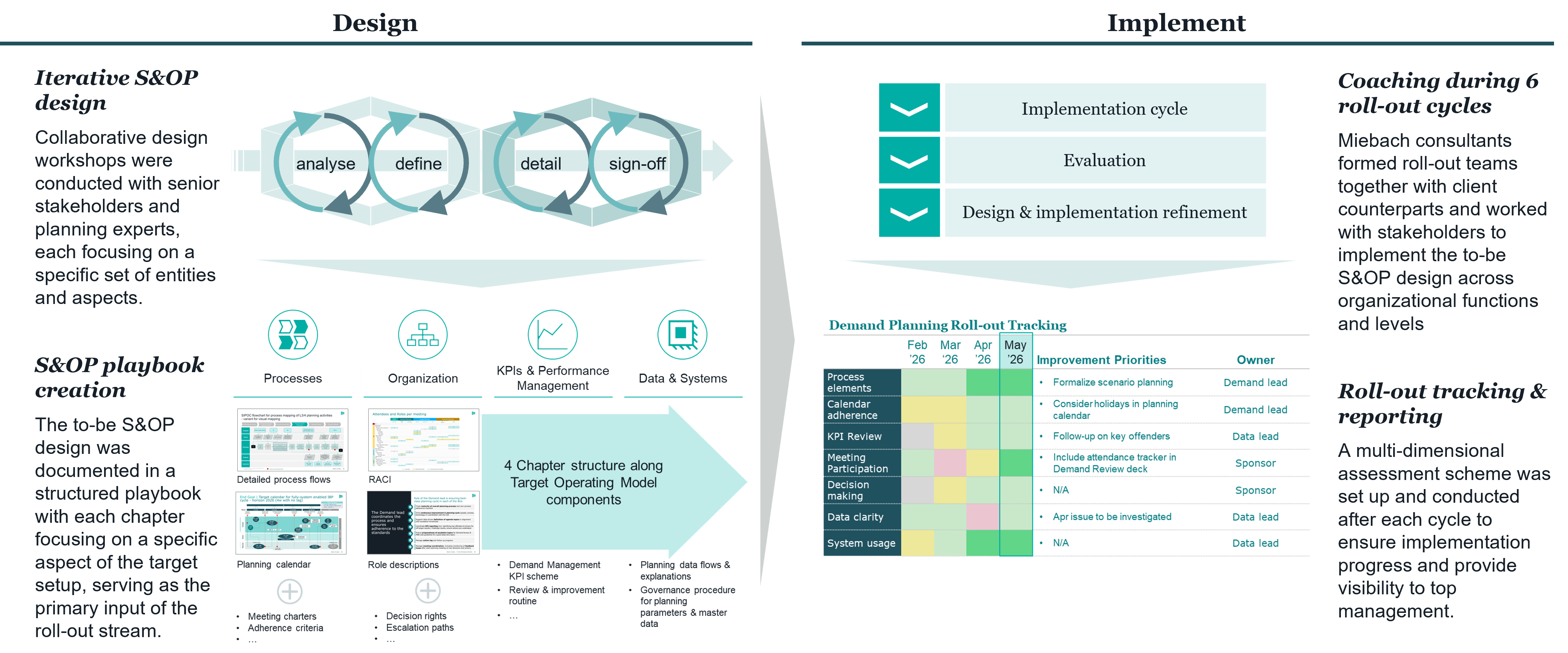

- Miebach was brought in to help design, implement and coach the transition to a standardized, multi-level S&OP process across all business units

- The primary design deliverable was the creation of an S&OP handbook, defining the to-be setup of the tactical planning operating model considering multiple perspectives (meeting structure, calendars, KPIs, data)

- The target of the subsequent roll-out phase was to successfully implement the defined decision meetings as well as preparation and follow-up processes and gradually bring them to target maturity

Solution

Miebach led the collaborative S&OP target design and teamed up with the client´s business owners to ensure a successful roll-out.

Results

The implemented target S&OP process significantly improved business alignment and key performance indicators.

Noticeable general alignment improvements between business functions

As one element of project success tracking, business leaders as well as involved planning process owners were surveyed on their perceived tactical planning alignment. They reported significant positive development in several key areas.

Measurable KPI impact already during project timespan

Applied monitoring instruments also confirmed measurable improvements across process adherence, planning maturity and key supply chain performance indicators.

| 87% Target process adherence score achieved across all tracked elements still during roll-out support |

-110m € |

+0.4 |