Next-Gen Automation in Brownfield Logistics: A Smart Response to Economic Pressure

By Sascha Kalytta, Senior Consultant, Miebach Germany, Berlin and Alexander Katona, Senior Consultant, Miebach USA, Fishers Indiana

24.11.2025

As economic pressures intensify across global supply chains, automation is no longer a question of “if” but “how.” For logistics and operations leaders facing space constraints, rising labor costs, and tighter budgets, brownfield automation offers a compelling strategic path. By equipping existing facilities with modern technologies, companies can tap into hidden potential, boost throughput, and make their operations future-ready, without the cost and time investment of greenfield development.

More important than ever: brownfield automation with new technologies

The Case for Brownfield Automation

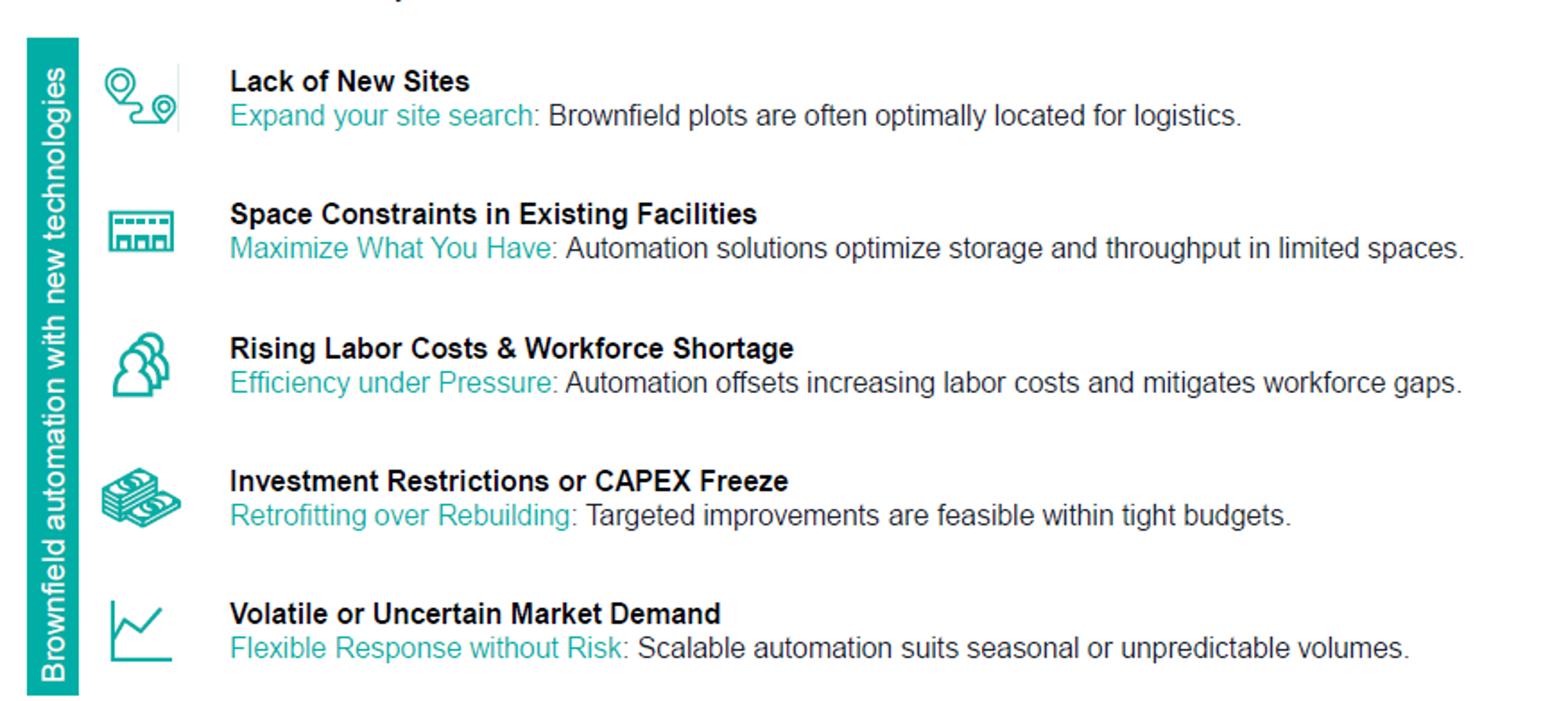

Brownfield automation is emerging as a high-impact response to the logistics sector’s most pressing challenges:

Labor Economics: With double-digit increases in labor costs across many regions and continued workforce shortages, automation offers both cost mitigation and operational continuity. Companies that have implemented targeted automation upgrades report labor savings of 20–40%.

Facility Constraints: Many older distribution centers and warehouses lack the capacity to support modern throughput demands. High-density automation systems, such as cube-based storage or robotic shuttles, can increase space utilization by up to 30%.

CAPEX Limitations: In a climate where large capital projects face more scrutiny than ever, brownfield automation enables a modular, step-by-step approach. This allows companies to stay within tighter investment cycles and deliver ROI typically over multiple years, depending on the specific solution and complexity. Demand Volatility: Scalable automation technologies enable businesses to adapt quickly to seasonal swings or unpredictable demand, without tying up capital in fixed assets.

Location Optimization: Brownfield sites are often strategically located near urban centers, transport routes, and workforce hubs. This provides advantages that new greenfield locations can’t always match.

Next-Gen Automation Technologies for Brownfield Environments

Today’s automation toolkit spans both traditional systems and emerging innovations, tailored for space-constrained environments:

Traditional Systems: Miniloads, shuttles, mobile shelving, and conveyor systems remain foundational for many retrofits.

Emerging Technologies: Rack-climbing robots, robotic shuttles, collaborative robots, and piece-picking systems brings new levels of flexibility, speed, and resilience to existing facilities.

Key Implementation Benefits

Brownfield automation offers a range of tangible advantages that make it both efficient and future-ready:

Storage Density: Cube systems and multi-level robotic storage deliver high throughput within tight footprints.

Scalability: Performance and capacity can be scaled independently, allowing operations to grow dynamically as needs evolve.

Redundancy & Uptime: Distributed systems reduce reliance on single points of failure, ensuring greater reliability and continuous operation.

Layout Adaptability: Technologies now support irregular building geometries, including sloped ceilings and segmented fire zones.

Implementation Challenges – and How to Overcome Them

Despite the advantages, brownfield automation requires managing complexity across multiple dimensions:

IT Infrastructure: Legacy WCS, PLCs, and WMS platforms often lack modern interfaces. To bridge this gap, middleware, API layers, and phased integration strategies are essential. Data standardization and visibility into system dependencies should be addressed upfront to avoid cascading issues later in the process.

Project Scope & Governance: Clear system boundaries and well-defined stakeholder roles are essential for success. Without them, projects can easily run the risk of scope creep, misalignment, and unplanned changes. A strong change management framework helps keep implementation on track and ensures operational stability throughout.

Construction & Permitting: Physical modifications, such as new equipment foundations, modified fire exits, or rerouted HVAC systems, often need regulatory approval and updated building certifications. Early coordination with authorities and expert planners can mitigate timeline delays.

Material Handling Integration: Retrofitting within operating sites comes with its own structural and planning challenges. Installations typically need to happen outside of peak hours, with clearly defined equipment transport routes and strengthened safety measures to keep operations running smoothly.

Why New Tech Works Better in Old Buildings

Unlike traditional systems that require standardized environments, new-generation technologies are designed to handle complexity head-on:

Fast Deployment: Modular setups enable phased rollouts with minimal disruption to daily operations.

Built-in Redundancy: Smart automation designs avoid single points of failure, ensuring higher uptime.

Flexible Fit: AMRs, collaborative robots, and rack-climbing solutions adapt easily to fragmented layouts and aging infrastructures.

Together, these features make them a perfect fit for logistics centers operating in decades-old buildings with limited documentation or design flexibility.

Strategic Questions for Brownfield Automation Planning

Before moving forward, logistics leaders should align all stakeholders around key decision points:

Performance modeling: How will automated systems work alongside ongoing manual operations? In many cases, a hybrid workflow proves to be optimal.

Investment justification: Can brownfield automation deliver comparable ROI to greenfield alternatives? What are the full lifecycle cost implications?

Site-specific planning: How will structural limitations, such as multiple fire zones or segmented halls, impact layout and compliance?

A solid feasibility study, grounded in real operational data, is essential to validate the true value creation potential of automation.

Conclusion

Brownfield automation is no longer a tactical fix – it’s a strategic enabler. By reimagining legacy facilities with next-gen automation, supply chain leaders can achieve faster throughput, greater resilience, and sustainable cost advantages. In an era defined by disruption, brownfield retrofits are how supply chains bend, not break.

Let’s unlock the potential of what already exists. Let’s make automation real, right where you are.

Authors