Process Design, Efficiency Improvement & Operational Planning

In the complex environment of supply chain operations, inefficient processes can quickly drain resources, erode profitability, and hinder growth potential. Effective process design – one that integrates cost efficiency, optimizes throughput, and focuses on exceptional service – is vital to establishing resilient and scalable operations.

Relevance of Capability

Whether your organization is launching new operations, revamping existing ones, facing persistent bottlenecks, productivity gaps, or preparing to introduce automation and digitization, the stakes of getting process design “right” are considerable. The proper alignment of people, equipment, and workflows is key to your operational agility and long-term competitive advantage.

When Is This Relevant?

Organizations typically require process design

and efficiency support when:

- Launching new operations or expanding into new markets

- Experiencing bottlenecks, low productivity, or high labor costs

- Preparing for warehouse automation or process digitization

- Facing underutilized assets or outdated standard operating procedures

- Seeking to improve service performance while managing costs

- Changes in trade regulations, environmental standards, or customer expectations force to revisit the SC processes.

- Increasing flexibility, adaptability and resilience in the E2E Supply Chain

- Mergers or Acquisitions require to integrate and harmonize their supply chain processes

Challenges Faced

Designing supply chain processes is essential, but it’s also challenging because of:

- Complexity of global Supply Chains

- Cross-functional alignment

- Resistance to change

- Data and visibility issues

- Technology integration

- Balancing standardization and flexibility

- Managing risk and uncertainty

These challenges often result in delayed throughput, rising operational costs, and reduced customer satisfaction.

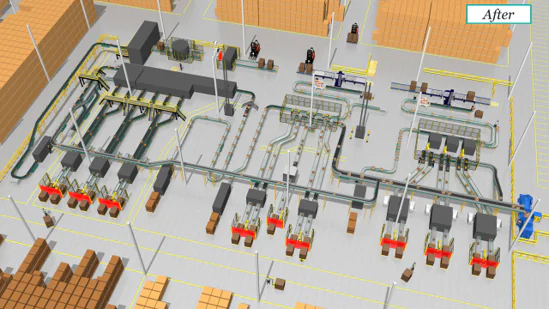

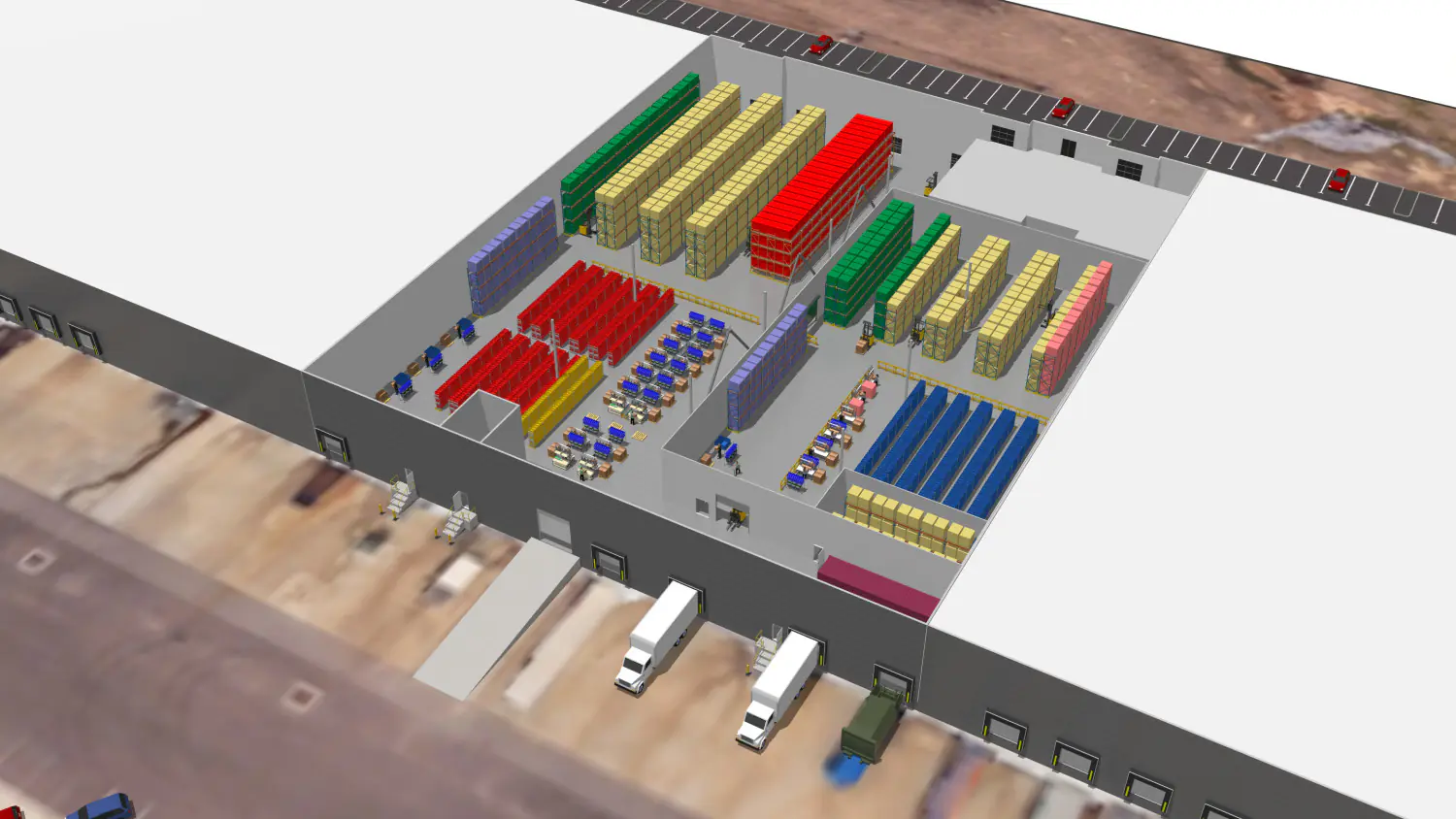

The Miebach Difference

Miebach’s distinctive approach merges precise engineering with real-world practicality. Our experts develop process designs firmly rooted in empirical data and tailored explicitly to your unique volumes, operational constraints, and overarching business goals. Our solutions are designed to function seamlessly in actual operational environments - not merely as theoretical constructs. Starting with your strategic business objectives, we utilize a wide array of advanced simulation tools, warehouse modeling, comprehensive time-motion studies, Theory of Constraints analyses, and Lean Six Sigma methodologies. These rigorous approaches enable us to test and validate process designs thoroughly before actual implementation, significantly reducing risks and enhancing operational success.

Partnering with Miebach positions your business to achieve streamlined, efficient, and highly adaptable operations – the essential foundations for sustained growth and competitive strength.

What can we help you with?