Process Automation

Introduction

Many supply chain organizations are held back by manual, repetitive, and error-prone processes that span multiple systems and stakeholders. Despite investments in WMS, TMS, ERP, and planning tools, critical workflows such as order handling, billing, exception management, and information exchange still rely on human intervention. This leads to high workload, long cycle times, limited scalability, and inconsistent execution. In an environment characterized by volume volatility, labor shortages, and cost pressure, these inefficiencies directly impact service levels and profitability.

Capabilities

Why Process Automation is relevant and Miebach’s Approach

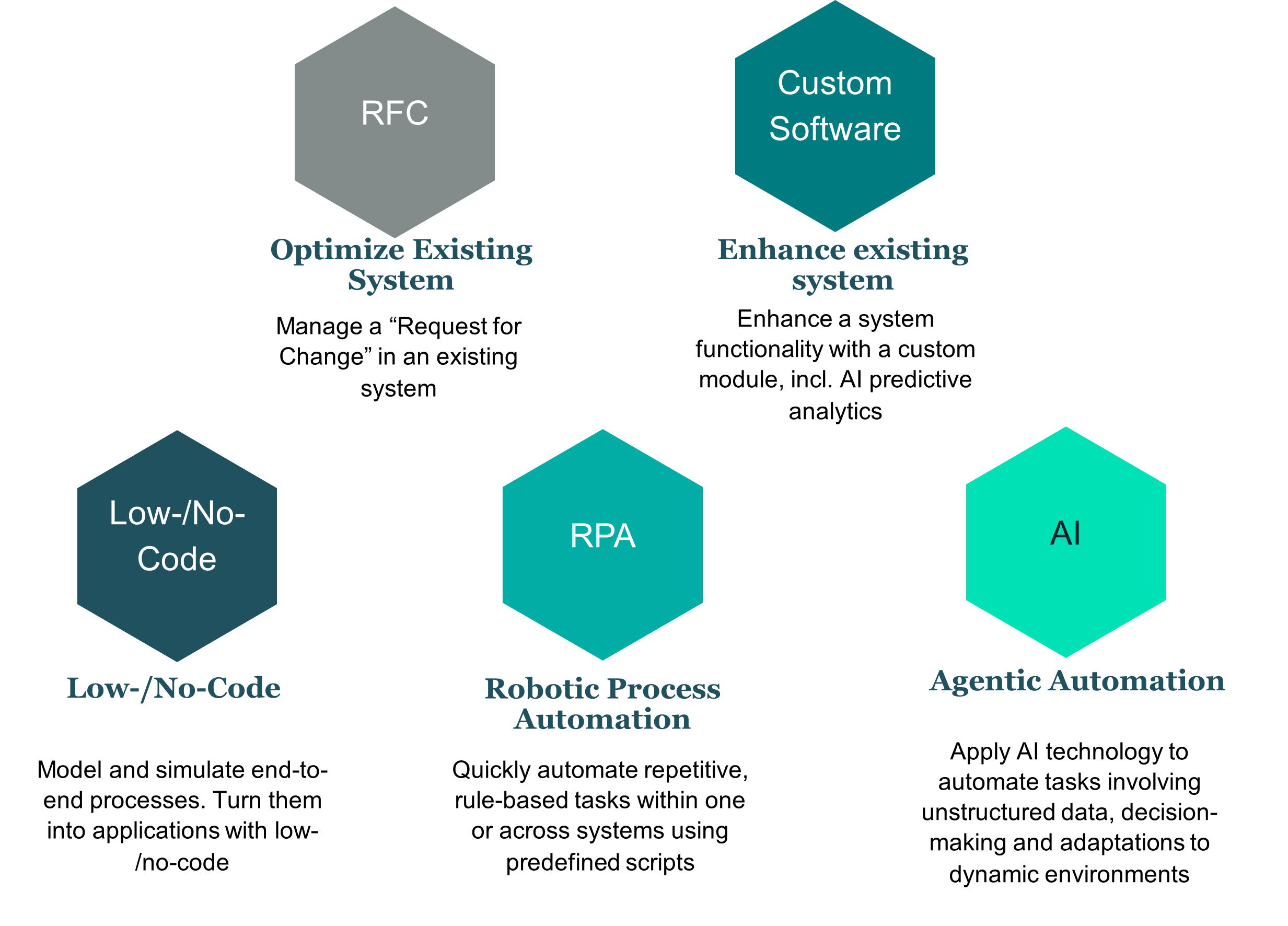

Miebach’s Process Automation services systematically transform manual and semi-digital supply chain processes into efficient, scalable, and resilient digital workflows. Building on a profound understanding of the physical and information flows, we design end-to-end automated processes using the most suitable technologies – ranging from low-/no-code platforms and robotic process automation (RPA) to AI-based and agentic automation or custom software modules.

Our approach ensures that automation is not implemented in isolation, but fully aligned with target processes, system landscapes, and business objectives. The result is a pragmatic automation roadmap that delivers quick wins while creating a foundation for long-term operational excellence.

Common Use Cases

Automation

…of repetitive, rule-based tasks across WMS, TMS, ERP, and planning systems (e.g. order creation, data validation, billing)

End-to-end digital workflows

… for order intake, delivery documentation, and invoicing to improve speed and accuracy

AI-supported automation

… for processes involving unstructured data, such as emails, documents, images, or dynamic decision logic