3-D Enabled Facility Design

Blueprints you can walk through

Executive Summary

Too many warehouse projects stall not because of bad ideas, but because decision-makers can’t clearly see the vision. Abstract 2D floorplans and technical drawings leave executives and other stakeholders guessing at how the design will actually work. The result is hesitation, slower decisions, and the risk of expensive change orders once reality catches up.

3-D enabled design closes this gap. By transforming technical plans into clear, immersive visuals, it creates a shared language across engineers, executives, and operations teams. Layouts and automation investments stop being abstract concepts and become something stakeholders can see, understand, and believe in.

Integrating 3D into early design phases turns uncertainty into momentum. By driving faster alignment, earlier buy-in, and greater transparency, it builds confidence across all levels of decision-making. With a shared understanding of the solution organizations can make decisions quickly and move forward with clarity and conviction.

Designing for a New Era

Why today’s supply chains demand faster, smarter design tools

Warehouses, distribution centers, and other supply chain facilities are being designed and redesigned at an unprecedented pace. The rise of omni-channel fulfillment, the evolving role of automation, and changing customer expectations are reshaping facility requirements and pushing complexity to new levels.

At the same time, decision-makers are under pressure to move faster. Approval cycles that once spanned months are compressed into weeks despite capital investments growing larger and attracting greater scrutiny. Aligning a wider set of stakeholders, each with different priorities and levels of expertise, has become both more critical and more challenging.

In this environment, 2D drawings and technical floorplans are no longer enough. Approaches that once worked now slow down decisions, foster misalignment, and raise the risk of costly mistakes. Today’s projects demand design processes that are faster, more visual, and more accessible to leaders beyond the engineering world.

This is where 3D-enabled facility planning proves its value. By transforming complex designs into clear visuals, these tools enable better conversations, earlier alignment, and stronger confidence in investment decisions without sacrificing the rigor of traditional approaches.

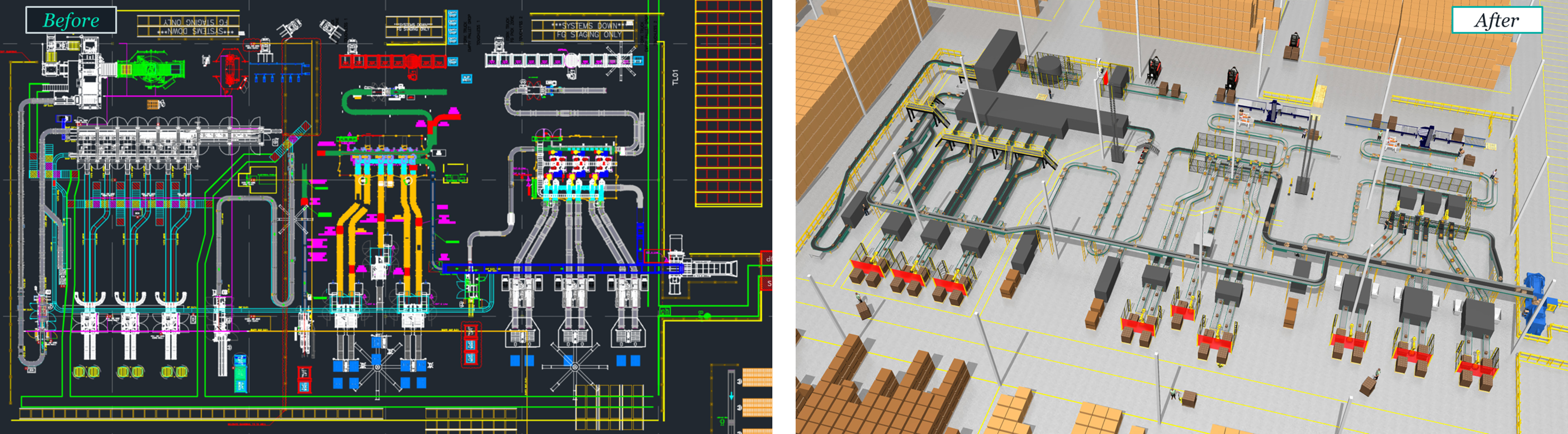

Figure 1: Visualization

From Concept to Consensus

How incorporating 3D into the design process accelerates alignment

The concept design phase sets the foundation of any facility project. Whether it’s a greenfield build, facility expansion, or brownfield retrofit, the goal is to define the direction of the project and evaluate its impact by comparing multiple feasible alternatives and allowing leadership to select the most effective path forward.

Traditionally concept design has relied on 2D plans or block diagrams to show how a space might be utilized, but incorporating 3D visualization bridges the gap between concept and reality. It complements the technicality of 2D drawings with more realistic, custom visualizations of what the future system could look like.

Step 1: Establishing the framework

Like any successful design, the process begins with foundational information: the design base. Order data, growth forecasts, and current layouts will form the backbone of the analysis that defines future requirements.

At this stage 3D visualization is not about presenting concepts or imagining the future. Instead, its value lies in validating existing layouts and spotlighting physical constraints that could impact the project. The resulting model serves as a reliable baseline template, providing a foundation for the design alternatives.

Step 2: Developing Layout Options

With inputs aligned and the design base established, the next step focuses on turning data into tangible designs. Using the parameters defined in Step 1, system designers begin shaping alternative layouts that explore different approaches to technology, flow, and capacity.

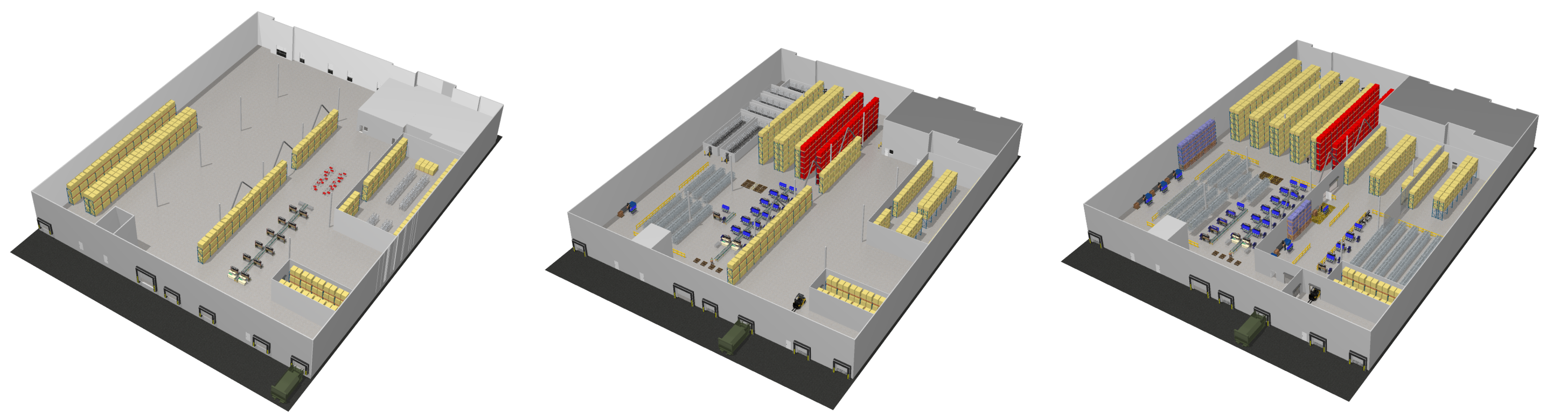

3D modeling makes this exploration faster and more insightful. Starting from the as-is model, system designers can test how varying levels of automation, storage configurations, or process flows would function within the larger building. Instead of relying on simplified block diagrams or high-level 2D plans, each concept can be built as a spatially accurate and visually engaging model that show not only where systems fit, but also how they interact.

This visualization focus yields a design process that feels more tangible and intuitive. Stakeholders can see how each design would operate, visualize new technologies, and compare alternatives side by side. Discussions shift from interpreting drawings to evaluating how each system fits the operation, allowing teams to build consensus around the best alternative.

SIDEBAR

Figure 2: Workshopping in 3D

Live design workshops in 3D allow teams to test layout ideas together in real time. Quick adjustments can be made as inspiration strikes. The result is a hands-on way to discover what configurations work best.

Step 3: Securing Stakeholder Alignment

The final and perhaps most critical step in concept design is securing alignment on the final design across all stakeholders. Operations teams want workflows that are intuitive and reliable. Finance and procurement teams focus on accurate, flexible cost models. Executives need assurance that the facility transformation supports long-term strategy and growth. Each group brings its own priorities, perspectives, and levels of technical expertise, making alignment essential but difficult to achieve.

3D visualization can be leveraged as a bridge to connect these different points of view. Renderings provide a realistic preview of the facility to help stakeholders understand how systems and processes come together in context. Animated flythroughs illustrate how products move through the building while 360-degree renders can be paired with VR technology to allow users to experience the space firsthand.

These 3D tools do more than just illustrate the design. They enable shared understanding by providing a common language to make discussions more productive, reduce design uncertainty, and build confidence in the chosen solution. Together this creates a unified vision of the future.

Conclusion & Call to Action

Leveraging 3D visualization throughout the design process brings conceptual ideas to life. As more consultants, integrators, and equipment manufacturers embrace 3D tools, it is becoming clear that 3D is no longer just an enhancement but rather the new language of facility planning.

In the ever-changing supply chain landscape the next era of warehousing design will belong to those who can align quickly, communicate clearly, and make decisions with confidence. This makes 3D-enabled planning not just a tool, but a competitive advantage across all stakeholders.

Contact