Case Study: Maximizing Space, Minimizing Risk

Client: Specialty Pharmaceutical

Warehouse Optimization That Delivers

Business Challenge

A pharmaceutical company in the specialty drug distribution and third-party logistics (3PL) spaces reached a critical

turning point in operational strategy for their primary distribution center: their existing layout was no longer able to support projected business needs. Previous demand only required use of about half of their available space. While this setup had been sufficient in the past, the anticipated business growth of 64% in 2025 and an additional 44% in 2026 meant that they needed a strategic approach to maximize their available footprint.

Additional challenges stemmed from the dual nature of the business operating under the same roof. The growing 3PL

operations required specialized handling and storage features to meet the needs of existing clients and attract new business. At the same time, specialty distribution must maintain strict product segregation from 3PL inventory to reduce the risk of handling errors. The facility redesign needed to effectively support both business models and their unique requirements while leveraging synergies between the two for optimized material flow.

Solution Delivered

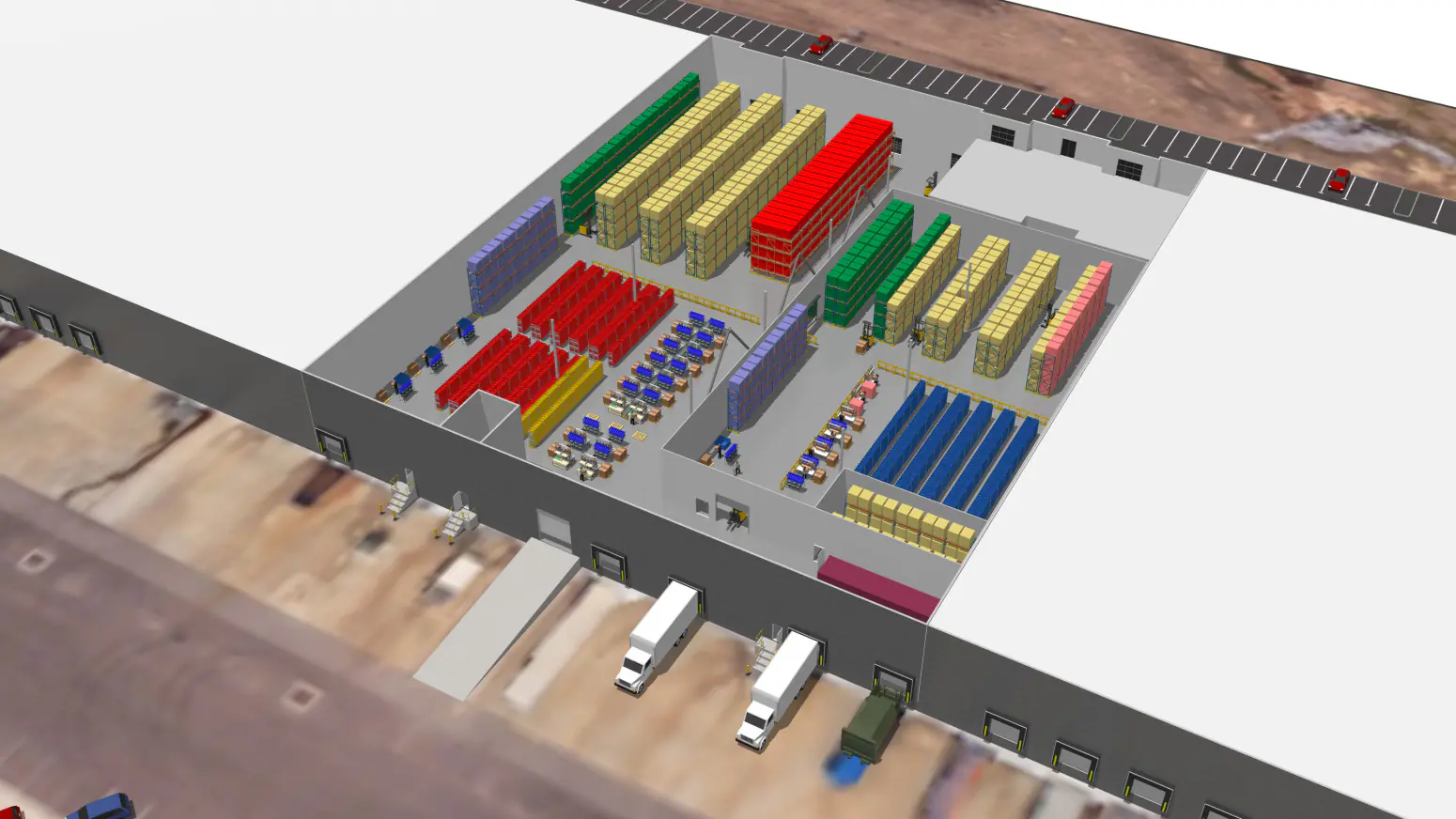

To help our client address their operational challenges and effectively utilize their entire available space, we developed a comprehensive warehouse optimization strategy focused on maximizing capacity, improving operational efficiency, and ensuring long-term adaptability. Operationally, the solution focused on streamlining material flow while ensuring appropriate product handling and segregation. The expanded cooler design integrated new chilled packing and receiving areas for better handling of temperature-sensitive products. Receiving and quarantine areas were also optimized, allowing for a more streamlined inbound process that enhances efficiency and ensures proper product handling from arrival to storage.

On the outbound side, the design established separate packing areas and processes between the two business segments to minimize risk of fulfillment errors. A critical aspect of the project was the use of 3D modeling approach to refine the warehouse layout better visualize capacity scenarios. This iterative process allowed for real-time visualization of storage configurations, helping the client make informed decisions about space utilization and future expansion options. These models were also utilized to develop the phased implementation strategy to ensure that the facility could continue functioning efficiently throughout the transition.

Results & Benefits

The redesigned warehouse layout delivered significant storage capacity gains while maintaining operational flexibility. The new design enabled significant increases in pallet and bin locations, ensuring the facility could support both immediate and long-term growth projections. The new storage strategies deployed for cases and packing materials allow for greater flexibility and optimized storage density. Additionally, the expanded cooler storage provided the necessary space for future temperature-sensitive inventory, while the segregated material flow design reduced handling risks. Most importantly, the phased execution strategy will enable seamless implementation, ensuring no disruption to daily operations.

This project not only positioned the company for sustained growth but also established a more flexible and resilient

supply chain, allowing the distribution center to adapt quickly to changing business needs. With an optimized layout,

improved material flow, and increased storage capacity, the client is now better equipped to handle future expansion and market demands with confidence.

Contact:

Canada United States

Angelica Rodriguez

Senior Manager, Engineering Practice Lead