Transport and Cost Optimization - Focus on Inbound Logistics

02.04.2024 | Written by Andreas Hartwig, Miebach

The Focus on Inbound Logistics

The basic model

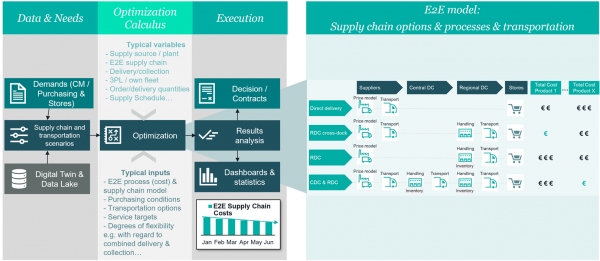

The basic model consists of three components: the data side, the optimization calculus, and the execution side.

Components for Optimizing Inbound Logistics

The following components are needed for optimizing inbound logistics:

- Data: Transport options/conditions, purchasing conditions/discount tiers, information and requirements from suppliers, items, and stores

- End-to-end supply chain model: granular process cost and capacity model of relevant delivery routes up to the shelf or end customer

- Optimization: a powerful, tailored optimization solution

- Execution: processes and software for efficient scenario comparison as well as making, implementing, and controlling supply chain and transport decisions

The interaction of these components enables efficient, ongoing optimization today, which increases achievable benefits, especially with a focus on inbound logistics.

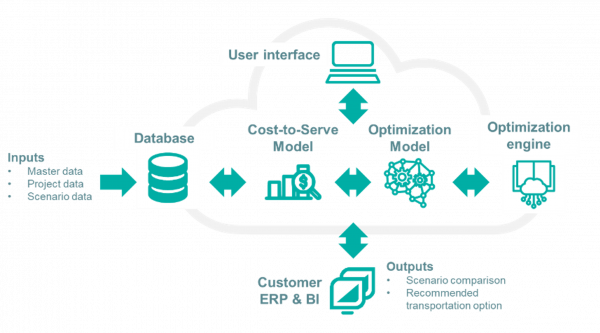

The User Interface

For tactical, mid-term decisions concerning supplier and supply chain selection as well as transport organization, aggregated future data is used. This can be refined for optimization using detailed historical data. For operational decisions, "real-time" data is required, enabling agile adjustments for each delivery or order.

At the core of the calculus is an end-to-end model of transport, supply chain process options, and purchasing conditions. An optimization engine allows simultaneous decision-making on the best ordering behavior, the best route, and the transport of individual deliveries. A noteworthy development is the growing emphasis on inbound transportation, which can also be integrated with outbound delivery.

Regardless, users on the execution side should encounter minimal complexity when it comes to the various options and optimizations. This allows them to concentrate on continuously and pragmatically improving decisions and their implementation. The better the "use cases" are defined and reduced to essential factors, the more benefits one can reap, as they are more likely to be applied effectively. Ideally, the user has an app tailored to the individual use case. The option to design a simplified user interface and be more targeted is one of the innovations that inject new momentum into supply chain optimization.

Conclusion

Further drivers of development are improved capabilities of optimization engines and increasingly better data availability and data quality within the broader context of digitalization. Integrating and connecting company data and systems often account for a large proportion of the total project costs. The other key factor for effort and success is the intensive preparation and consolidation of use cases and calculations so that practical and optimal decisions can be made, and implemented directly whilst execution is monitored without any loss of quality. Determining the needs of a delivery, which supplier they come from through which stages, and with which carriers they arrive, to achieve cost-optimal store delivery service, is then no longer a random product but a planned continuous routine.

"But we simply wanted to improve our transportation costs," one may think, and a continuous, data-driven overall process may initially seem time-consuming. But you have certainly already realized the quick potential of this. There are additional, sustainable competitive advantages to be gained if you digitally breach your transportation and supply chain structure and succeed in mastering integrated control on a day-to-day basis.

The good news is that the opportunities are there and can be achieved step-by-step through a structured approach.

Author