Simulation & Digital Twin Solutions

Introduction

Connecting the virtual and the real world today, for continuous optimization

Imagine a supply chain that predicts disruptions and constantly keeps in shape. This isn’t a science fiction, it’s the best practice of continuous network optimization with supply chain digital twins.

Companies come to us when they want to move beyond static planning tools and gain a living, breathing model of their supply chain or shopfloor-operation. Some are evaluating vendors and struggling to separate hype from reality; others need help building or implementing a digital twin that goes beyond proof-of-concept to deliver measurable value. In both cases, they need a partner who understands the technology and the supply chain dynamics it must represent. With digital models such as digital twins, dynamic processes become visible – precise, risk-free, and realistic. In a secure test environment, we analyze dependencies, test scenarios, and deliver reliable answers to your what-if questions. Simulation becomes the foundation for strategic, planning, and optimization decisions – insightful, targeted, and future-oriented.

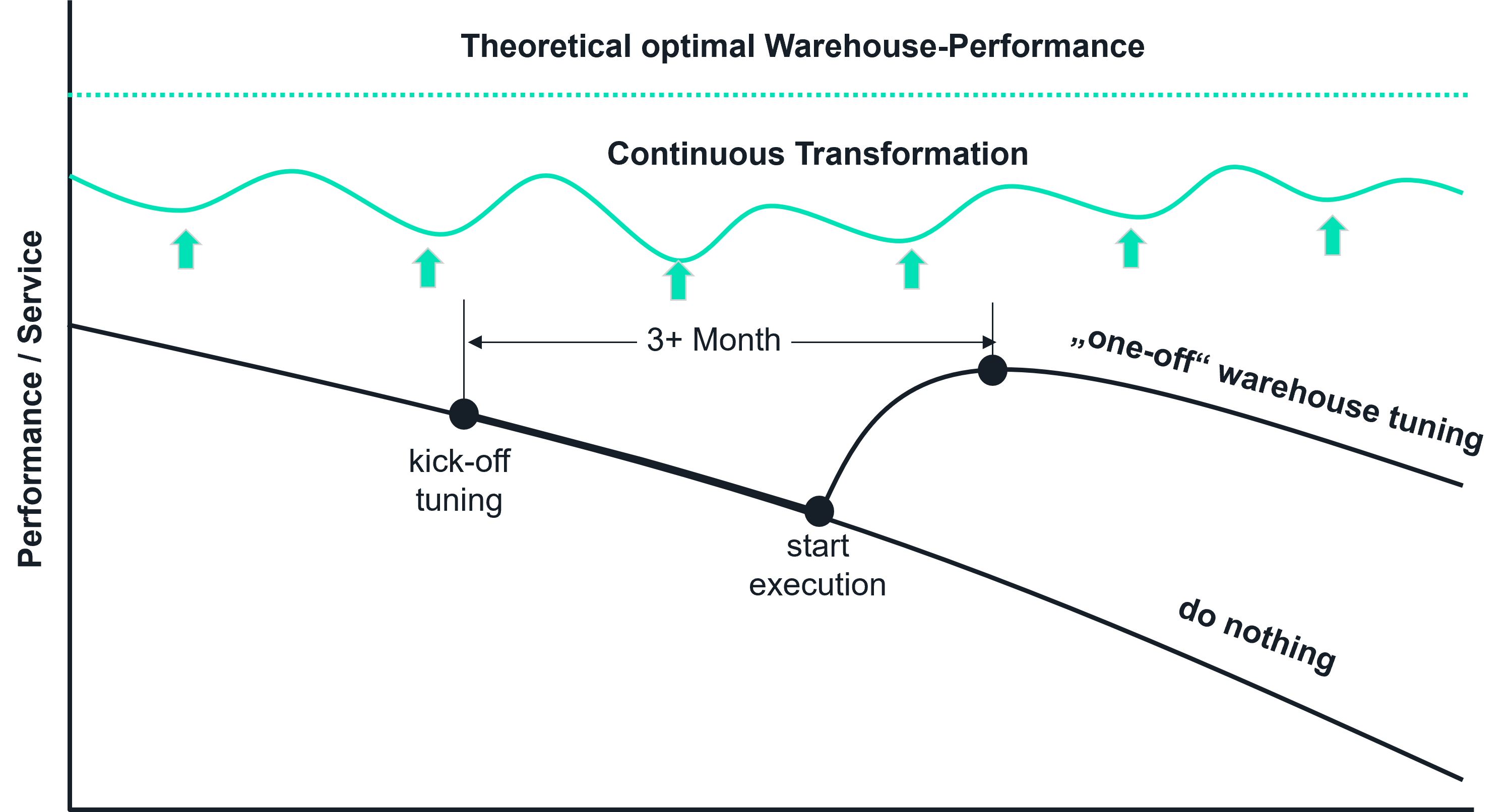

Figure 1: Digital Twin application has led to higher adaptability

What is a digital twin?

The digital twin comprises of:

- Data foundation – integrates, transforms, and aggregates data from various systems

- Cost-validated supply chain models for strategic, tactical and operational horizons at the relevant level of aggregation

- Software to manage these models, define scenarios and run analytics

- Self-serve apps and decision dashboards, democratizing the interaction with the models for non-experts.

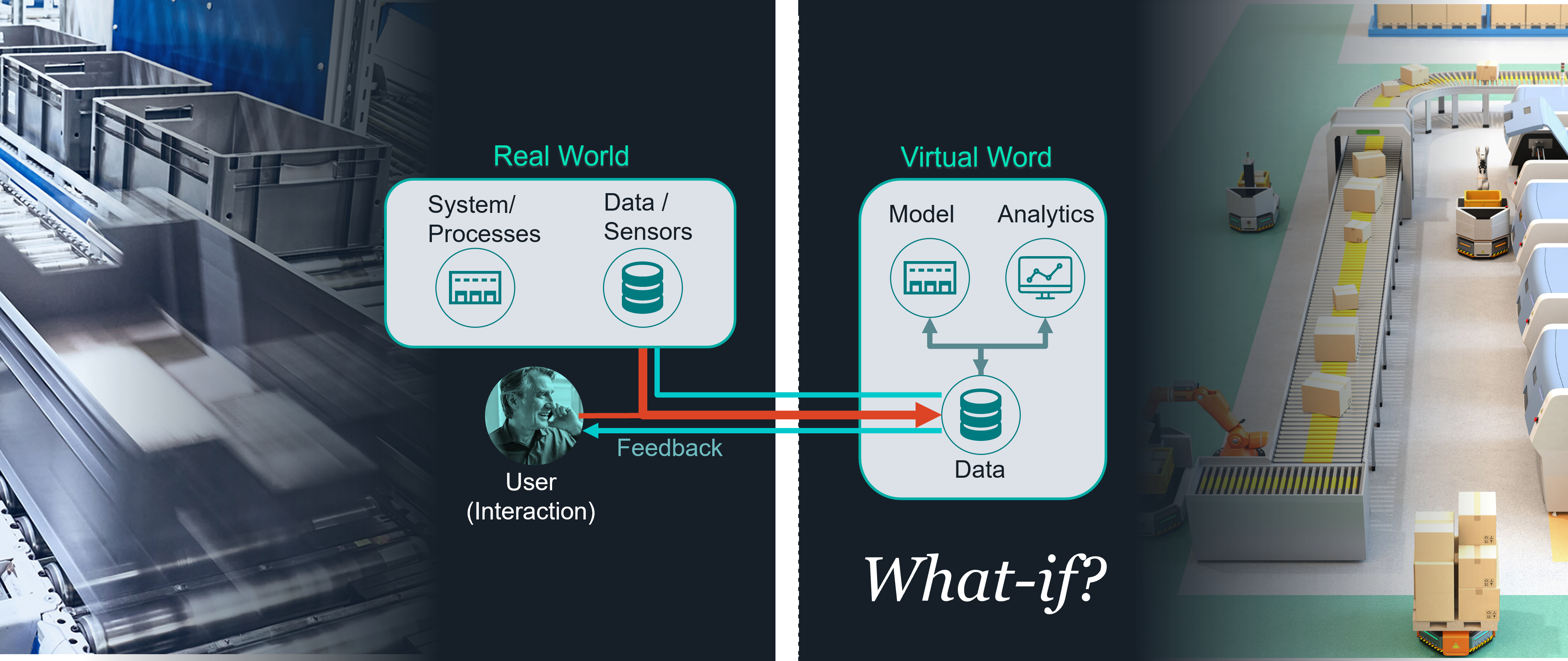

Figure 2: Decision-making through what-if-scenarios

Typical Challenges We See

- Uncertainty in vendor selection:

companies face a crowded market with overlapping capabilities. - Difficulty in capturing real-world complexity:

too often twins oversimplify, making them unusable in practice. - Integration hurdles:

without a strong data backbone, twins lack accuracy and trust. - Lack of adoption:

if planners and decision-makers don’t see the twin’s relevance, it quickly becomes a side project.

Relevance of Digital Twin

In today’s complex supply chain environment, digital planning and optimization tools are becoming key success factors. Companies leveraging simulations and digital twins gain a clear competitive edge through:

- Early identification and elimination of dynamic bottlenecks

- Optimization of control strategies and resource utilization

- Reduction of investment risks through validated decisions

- Objective decision-making independent of supplier interests

- Shared understanding between management, engineering, IT, and operations through visualized process models

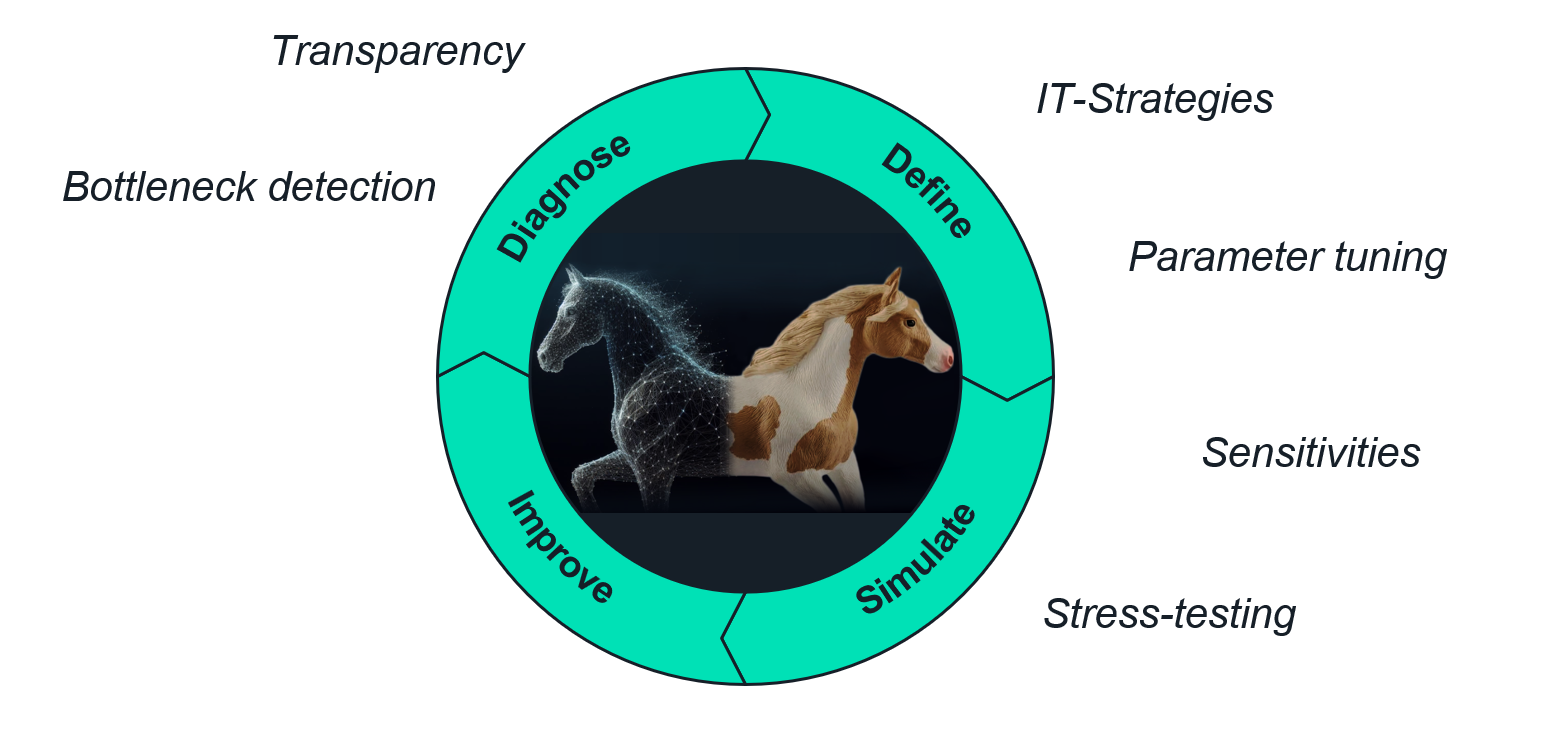

Figure 3: Smart Solution: Bottlenecks were detected, and effective counter-measures tested and implemented

Material flow simulations and digital twins enable the precise mapping, analysis, and optimization of complex logistics and production processes – from strategic planning to operational execution.

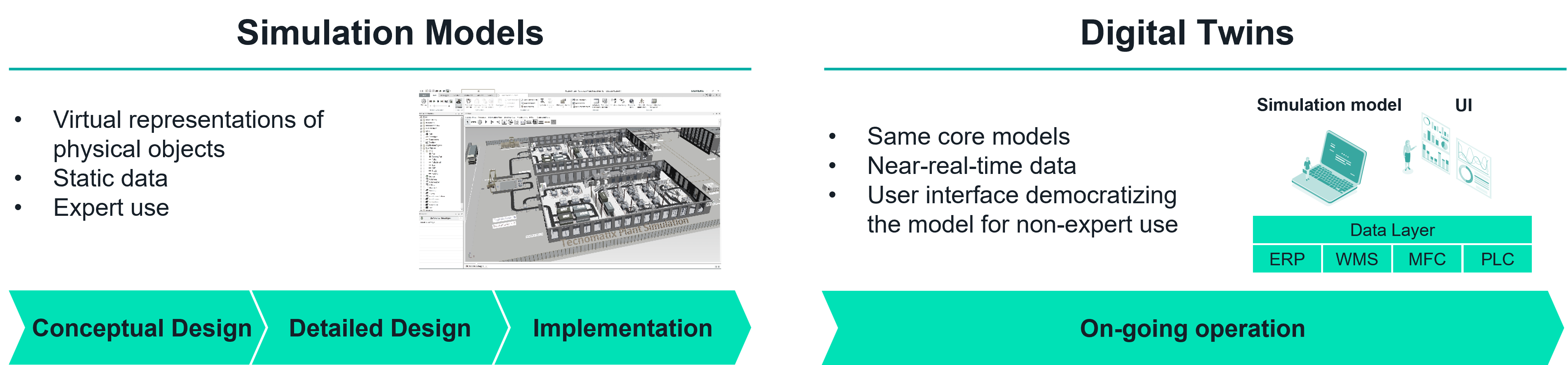

Figure 4: Simulation Models and Intralogistics Digital Twins

Market Relevance

Simulation capabilities and digital twins are no longer just “nice-to-have”, but an essential tools for informed decision-making in the design, operation, and transformation of logistics and production systems. Both fields are evolving rapidly, driven by greater computing power, advanced simulation software, IoT integration, and AI-based analytics.

- Rising Complexity

Global networks, multi-tier suppliers, and volatile demand have made supply chains harder to model and predict. - Technology Advancements

Cloud computing, IoT data streams, and AI have made large-scale simulations feasible where they once weren’t. - Pressure for Agility

Digital twins allow companies to test scenarios before making costly real-world decisions – a capability now seen as a differentiator. - Maturity Gap

Many vendors promise “digital twins,” but few deliver true end-to-end simulation and prescriptive insights.

The trend is clearly moving toward real-time transparency and predictive control.

Benchmark statements for digital twins and simulations

1. Up to 20% fewer instances of unplanned downtime.

Companies that use digital twin-based monitoring and predictive simulation reduce unplanned downtime by an average of 15–20%, particularly in automated production and logistics environments.

2. Productivity increases by up to 17%.

Using simulation-based digital twins leads to a ~17% increase in operational productivity, as bottlenecks are identified earlier and processes are planned more precisely.

3. 5–7% lower monthly operating costs

Digital twins enable data-driven decision-making in planning and control, reducing energy costs, resource usage and misallocations by 5–7% per month.

4. Reduction of errors in critical processes by over 70%.

Real-time monitoring, simulation and AI-supported root cause analysis can reduce errors in manufacturing, intralogistics and quality assurance by over 70%.

Summary:

- 20% fewer failures

thanks to predictive simulation and digital monitoring - 17% increase in productivity

through data-driven process optimisation - 5–7% lower costs

thanks to optimised planning - 70% fewer errors

through intelligent, simulation-based quality control

Common Use Cases

These methods are applied in both greenfield projects (new site planning) and brownfield scenarios (optimization of existing facilities and operations) – always with the goal of enabling informed, sustainable, and economically sound decisions.

The Miebach Difference

Miebach enables companies to make data-driven decisions built on a solid digital foundation – minimizing risk, enhancing efficiency, reducing costs, optimizing material flows and inventories, and protecting investments. Our approach is defined by independence, deep process understanding, realistic modeling, and a holistic view from strategy to operations.

Our Approach

- Objectivity and neutrality

No conflicts of interest: we advise solely in our clients’ best interests - Practical models

Realistic, validatable, and easy for all stakeholders to understand. - Technology independence

We select the most suitable tools based on project requirements. - Experienced experts

Interdisciplinary teams with expertise in logistics planning, IT, data science, and simulation. - Deep industry knowledge

With 20+ offices worldwide, Miebach understands the unique needs of industries from automotive to pharma, fashion to retail, and logistics services. - Sustainable value

Our simulations deliver more than results; they build strategic understanding and lasting improvements.

What We Deliver

- Strategic Guidance

Helping clients define what type of digital twin they truly need (network, operations, end-to-end). - Vendor Evaluation & Selection

Navigating the crowded landscape to match business needs with the right platform. - Custom Development

Where off-the-shelf tools fall short, we design and implement tailored models. - Robust Data Foundations

Ensuring the twin is fed with accurate, connected, real-time data from ERP, WMS, TMS, APS, and IoT sources. - Actionable Scenarios

From capacity planning to disruption response, our implementations focus on what decision-makers can act on. - Change & Adoption

We embed the digital twin into existing planning and execution workflows so it becomes a trusted tool, not a side project.

What can we help you with?