Automation & Robotics

Global supply chains face mounting pressures to improve efficiency, resilience, and safety, automation has emerged as a key enabler of transformation. Businesses across industries - automotive, pharmaceutical and life sciences, consumer goods, high-tech manufacturing, fashion and apparel, logistics services, chemicals, and retail - are embracing automation not simply to modernize but to remain competitive in a rapidly evolving marketplace.

Automation and robotics technologies offer powerful levers for increasing productivity, minimizing human error, and overcoming workforce constraints. With declining costs and expanding solution diversity, automation is now viable for a broader range of operations than ever before. Even amid economic uncertainty, companies can now realize strong returns on investment by strategically integrating automation into warehousing, material handling, and fulfillment processes.

Whether you're exploring automation for the first time or seeking to optimize and scale existing solutions, we meet you wherever you are at - from feasibility assessment to design, implementation, and go-live.

Relevance of Capability

Automation and robotics are no longer a future vision – their integration needs to be a top priority. Companies across industries are accelerating their adoption of automation technologies to meet performance goals and remain competitive. As hardware and software costs decrease and solution diversity expands, a strong ROI is more attainable than ever.

And companies that don’t? They’ll be left behind by their peers who made it a priority.

Automation drives measurable outcomes: higher throughput, reduced human error, better space utilization, and safer work environments. These technologies are central to addressing evolving challenges in supply chain design and execution in unpredictable times.

Market Context and Evolving Challenges

The rise of AI-driven automation is redefining what supply chains can achieve. Intelligent systems now support real-time data analysis, predictive maintenance, and dynamic adaptability, creating new possibilities for decision-making and operational agility. Meanwhile, collaborative robotics - or cobots - are being deployed to work safely and efficiently alongside human labor, bridging talent gaps and reinforcing workplace safety.

These technologies are becoming especially vital in intralogistics, where the use of AGVs and AMRs is accelerating rapidly. Warehouses and distribution centers increasingly rely on these systems to handle picking, packing, and internal transport with greater precision and speed. Industry momentum continues to build: research from MHI indicates that 83% of supply chain leaders intend to adopt automation and robotics within the next five years, with over half planning to increase their investment substantially. Of those, 60% expect to invest more than $1 million, and nearly 20% anticipate exceeding $10 million. This trend signals a fundamental shift toward automated operations as a cornerstone of supply chain strategy.

Automation technologies are also directly addressing some of the most pressing operational challenges businesses face, such as:

Skilled labor is in short supply, especially in physically intensive or repetitive tasks. Automation alleviates this burden and allows human workers to focus on higher-value roles

Inflation and volatility in transportation and wage costs necessitate leaner, more efficient operations. Automation improves throughput and reduces error-related losses

Faster delivery, real-time tracking, and greater customization have become the norm. Automation supports responsive, agile fulfillment models

Disruptions from pandemics, geopolitical events, or material shortages highlight the need for adaptable operations. Automation systems, especially those integrated with AI, enable dynamic responses

Supply chains generate massive amounts of data. AI-enabled automation supports predictive maintenance, decision support, and improved transparency across systems

Automation not only relieves the burden of repetitive and physically demanding tasks but also enables teams to focus on higher-value work. It enhances resilience by allowing operations to adapt more swiftly to disruptions, such as demand spikes or supply shortages, and by leveraging AI to distill complex data into actionable insights that improve visibility and coordination across the supply chain.

The Miebach Difference

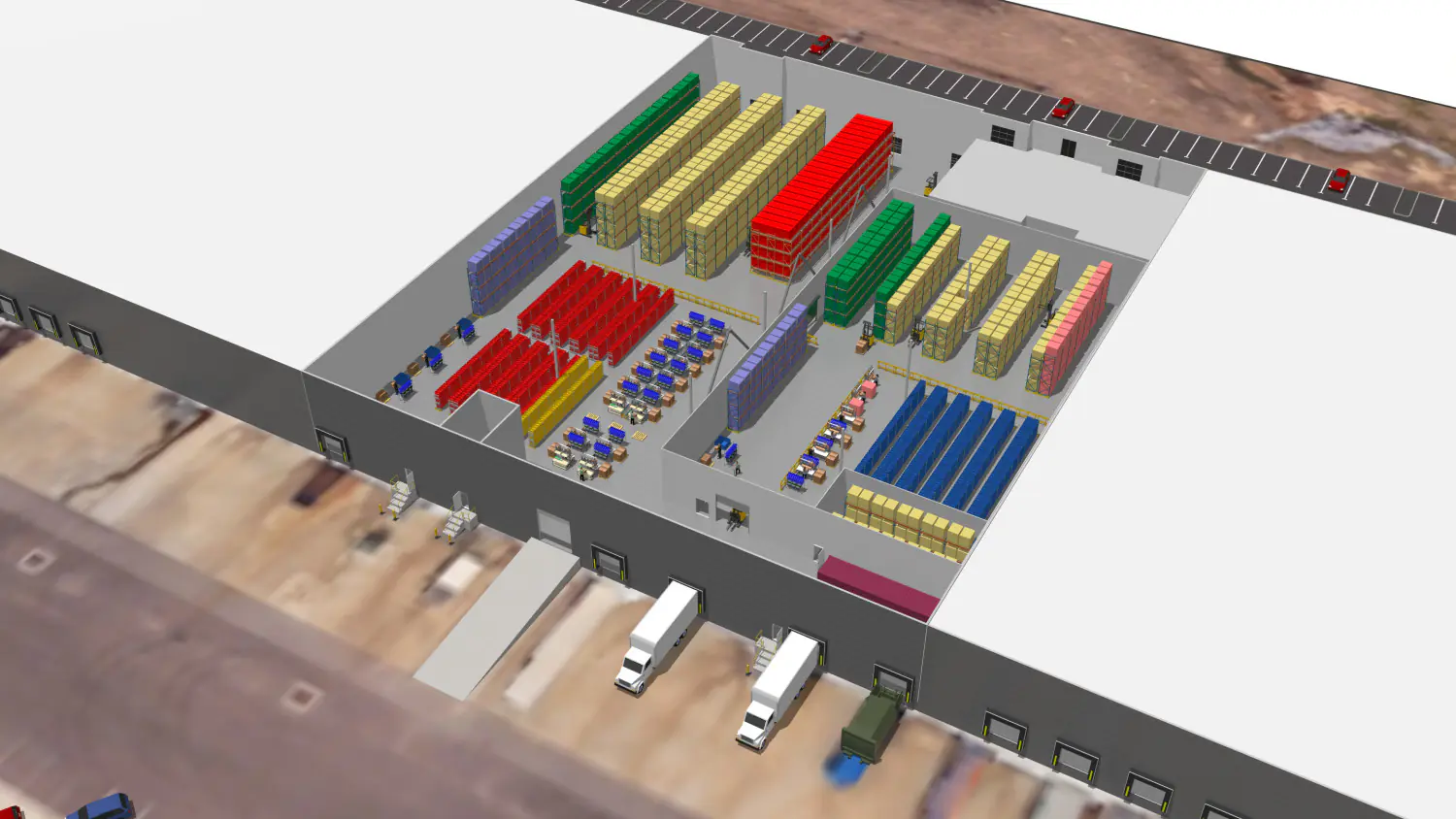

Miebach empowers clients across industries to embrace automation and robotics as essential pillars of supply chain transformation. Our approach is grounded in industry expertise, technical rigor, and a commitment to tailored, vendor-neutral solutions. We bring a thorough understanding in core application areas like automated storage and retrieval systems (AS/RS), shuttle systems, autonomous material transport using AGVs and AMRs, and robotic palletizing.

Miebach’s strength lies in our ability to guide clients through the entire automation lifecycle. Our project involvement spans from strategic assessments and solution design to tendering, implementation oversight, and post-deployment optimization. We take an integrated approach that considers all relevant components of a successful automation initiative, including building requirements, material handling systems, operational processes, and IT architecture. Our project management model aligns all roles and stakeholders - architects, contractors, system vendors, and internal teams - to ensure cohesive execution and measurable results.

Unlike automation integrators, we operate as an independent supply chain consultancy. We don't promote proprietary systems or push one-size-fits-all solutions. Instead, we provide impartial guidance, rigorously evaluating each client's specific context and requirements to recommend the most appropriate technologies and partners. Our independence is a key differentiator: it ensures that every solution is tailored, transparent, and aligned with your long-term business goals.

Clients also benefit from our strong relationships with leading automation vendors, which allow us to manage competitive tendering processes on your behalf. We act as your technical advocate throughout the selection and implementation phases, ensuring that decisions are made with full confidence and that the chosen solution delivers both technical excellence and strategic fit.

What can we help you with?