Synchronizing Production for Competitive Advantage

In a business environment where customers expect individualized products delivered at speed, the pressure on manufacturing and logistics systems continues to grow. To meet these demands, production and logistics must be more tightly synchronized than ever before. Digital technologies bring new challenges – but also powerful opportunities for greater productivity. The key to unlocking this potential lies in stable, lean processes.

At Miebach, we support you mastering this transformation by leveraging digital innovation, lean design, and proven, practice-based methodologies to enhance productivity and ensure sustainable success.

Challenges

Production must find answers to new, known and intensifying challenges:

| Order sizes | Investment Pressure | Personell | ||

|

|

|

||

| Digitization | Global Versus Local | Sustainability | ||

|

|

|

New Demands for Smart Production

Many companies struggle to utilize the possibilities of new technologies due to fragmented structures or outdated systems. That is where Miebach comes in to help you unlock your opportunities.

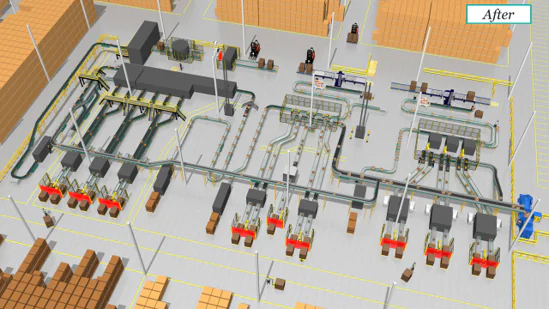

End-to-End Factory Planning

Our expertise spans the entire range of production optimizations, from greenfield factory setups to the optimization of existing plants.

Our approach for your success:

- Design production and logistics processes around value streams and material flows

- Develop master plans and block layouts

- Development of solution concepts and detailed layouts

- Conduct cost-benefit evaluations of alternatives

- Create phased implementation plans compatible with ongoing operations

- Provide end-to-end realization support

Result: You achieve increased productivity through effective processes, technology, and architecture. We place particular emphasis on involving your employees throughout the process. A practice-based simulation also provides you with a high degree of planning certainty.

|

Would you like to learn more about Smart Greenfield Factory Planning?

|

Smart Use of AI in Production

Artificial Intelligence is revolutionizing production, but only when applied where it matters most. We support you in identifying where AI can unlock the most value and support you in making implementation-ready decisions.

Our approach for your success:

- Analyze your production processes, technologies, and IT support landscape

- Identify company-specific AI use cases in manufacturing, assembly, and quality control

- Define predictive maintenance and planning and control scenarios

- Assess investment needs, expected benefits, and implementation effort

Result: You get a tailored roadmap for leveraging AI to create most value, be cost-effective, and aligned with the company’s digital maturity, leading to measurable efficiency and quality gains.

|

Would you like to learn more about AI in production?

|

Boosting Productivity Without Adding Capacity

Fluctuating demand requires appropriate capacity buffers, especially during peak periods. Capacity expansion is hardly economical, especially in times of limited investment funds. The key here is to identify productivity reserves in existing systems and make them usable.

Our approach for your success:

- Screen your production processes, material flows, and information streams

- Identify bottlenecks and prioritizing solution development

- Create targeted solution concepts for processes, layout, organizational structure, IT, and technology

- Support supplier tendering and evaluating proposals

Result: You get a customized solution based on proven best practices that delivers measurable productivity gains with minimal investment. We support you end-to-end from initial analysis to implementation.

|

Would you like to learn more about boosting productivity without adding capacity?

|

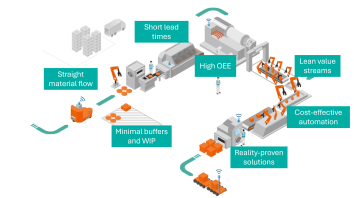

Value Stream Design and Lead Time Reduction

Long lead times, bottlenecks, and non-value-adding activities are common challenges in manufacturing. Through our value stream optimization programs in production and logistics, we systematically improve your processes and significantly reduce lead times

Our approach for your success:

- Measure lead times and pinpoint critical paths

- Define improvement goals in alignment with all stakeholders

- Analyze all planning and execution processes affecting throughput

- Eliminate waste with future-state, value-stream-based process design

- Drive implementation through change management and project controlling

- Establish systems for continuous improvement

Result: You gain shorter lead times along with improved cost efficiency, productivity, quality, and delivery reliability, thanks to strong stakeholder alignment and lasting process improvements.

|

Would you like to learn more about Value Stream design and Lead Time Reduction?

|

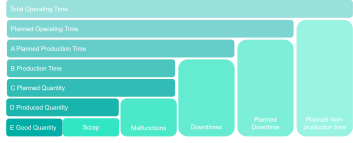

KPI Systems and Performance Control

Smart production needs smart control. That’s why we develop customized KPI systems to support operational excellence.

Our approach for your success:

- Establish a clear understanding of current and future business models

- Structure individualized KPI systems

- Support metric definition and data maintenance

- Assist in interpretation and deriving improvement actions

- Enable self-sufficient adaptation and evaluation of KPIs

Result: You achieve stronger operational control and improved decision-making based on clear, customized KPIs that are fully integrated into your organization and flexible enough to adapt as your needs change.

|

Would you like to learn more about KPI Systems and Performance Control?

|

From great ideas into proven results

Miebach has supported manufacturers across industries to achieve measurable performance improvements without the need for major capital investments.

Whether you want to redesign your production flows, optimize your factory layouts, or integrate digital tools, our hands-on approach ensures that the transformation does not stop at the concept phase: we deliver all the way to the shop floor.

Partner with us to turn your production into a competitive engine for growth.

What can we help you with?