AI in production – Revolution or the end of the Lean Approach?

28.02.2025 | Article by Dr. Reiner Friedland, Miebach

Artificial Intelligence (AI) is increasingly becoming a significant part of our daily lives, and it also offers great potentials for production systems. But does this mean that traditional methods of enhancing productivity are outdated and should be replaced?

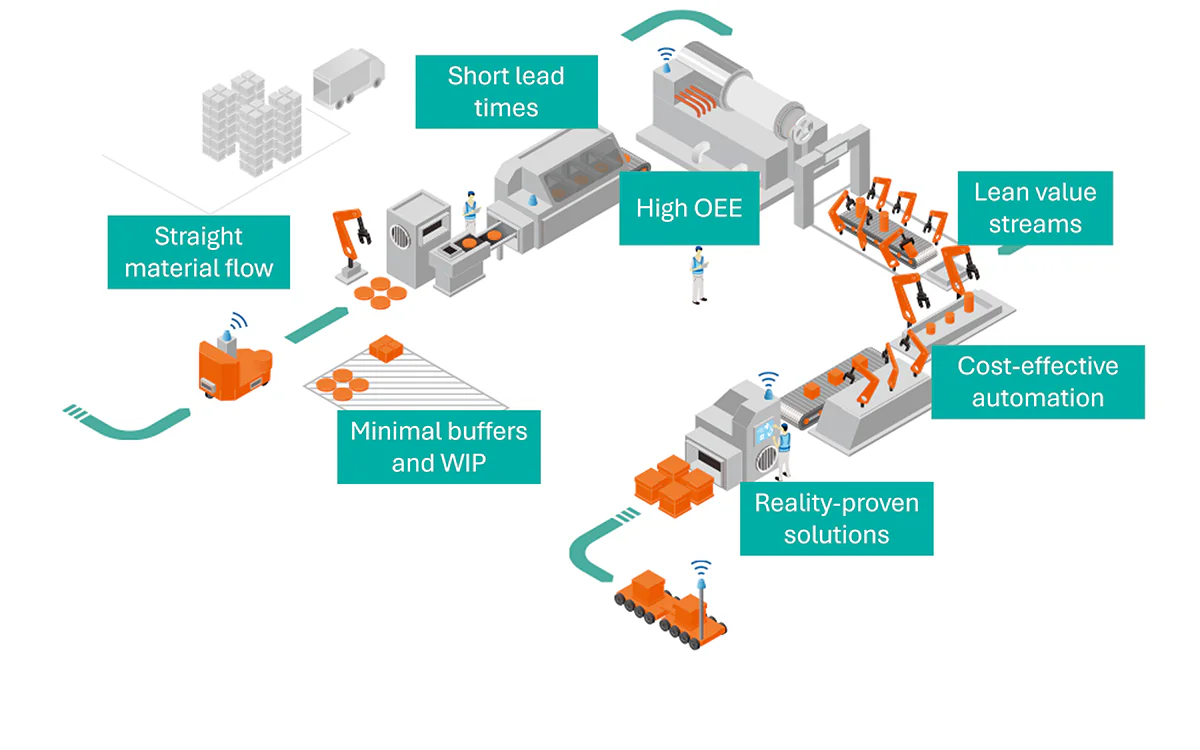

Capabilities of AI open more opportunities for further gaining of Lean potentials

Artificial intelligence – chance or risk?

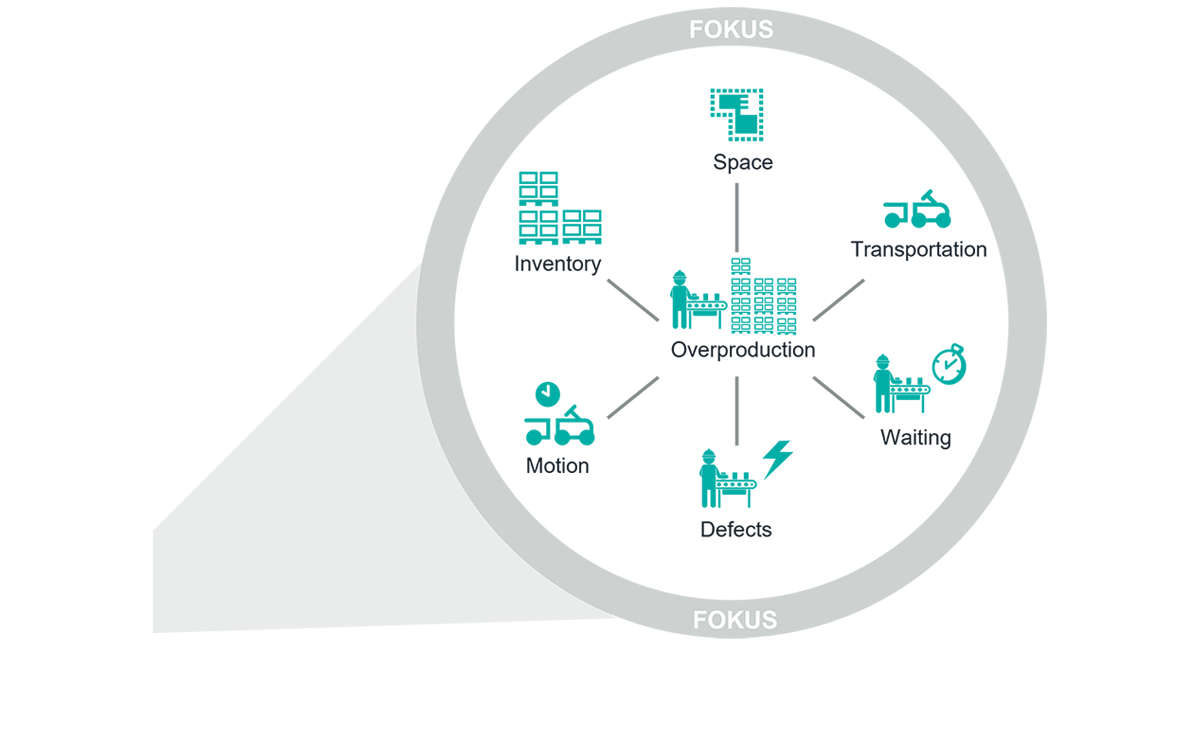

AI is seen as a game-changer for production systems, dominating current discussions. Despite agreement among many manufacturing leaders, some skepticism persists. Will AI's potential outweigh its risks? Should we fully replace established methods with new ones? Will AI make Lean obsolete?

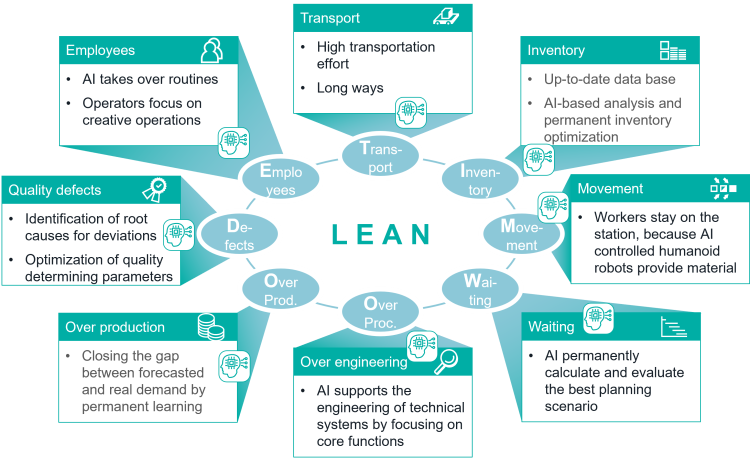

Let's clear up misunderstandings and offer some context: AI will not eliminate Lean. Instead, AI can support all aspects of Lean, as illustrated above.

Lean and AI – Partners in Success

Transport

In the future, transport will be managed more efficiently and quickly. Autonomous transport systems, including drones, will have real-time access to transport data. Continuous data analysis will enable AI to route materials to their destinations in production with maximum efficiency.

Inventory

Up-to-date data combined with customer and supplier information enables continuous optimization of inventory parameters. AI learns from past shortages or excess stock, continually adjusting to approach optimal levels.

Movement

Humanoid robots can support goods-to-person processes, bringing required materials directly to the workstation, allowing operators to stay in place and focus entirely on value-added tasks.

Moreover, the need for operators to leave their workstations is minimized because all information is readily available. AI delivers tailored information for each process step and workstation, specifically designed to match the qualifications of the operator on duty.

Waiting time

An intelligent digital twin of the production system continuously develops optimal production scenarios. A new order is released only if AI approves its fit with the current production situation, considering existing and forecasted bottlenecks to minimize waiting times.

Overengineering

AI methodologies can assist in analyzing the core functions of a technical system, reducing the risk of overengineering by avoiding the inclusion of unnecessary or potentially redundant components.

Overproduction

AI is learning from both forecasted and actual demands. By using these insights, the planned production program increasingly aligns with real demand, preventing overproduction.

Quality

AI assists in detecting quality deviations and their root causes early in the process. Additionally, by learning from past deviations, AI increasingly adjusts process parameters to optimal ranges.

Potentials for employees

AI frees us from repetitive, tedious, or harmful tasks, allowing operators to fully utilize their creativity in daily production and ongoing system improvements.

Conclusion

To conclude, it is clear that AI won't replace all our successful concepts from the past decades. Notably, the Lean approach remains relevant and will actually benefit from the capabilities brought by Artificial Intelligence.

The vast new capabilities will not make our experiences and improvements obsolete. Instead, AI and Lean work well together. The principle “Processes first, IT second” still applies. First, enhance your processes; this sets a solid foundation for further improvements with AI.

By combining Lean methodology with AI solutions, Miebach supports production companies in developing and enhancing improvement concepts.

Get in touch with us to unleash the full potential of your production value chain!

Author